Wood

With flame cutting, also known as oxygen cutting, a material is heated only to its ignition temperature. Oxygen is used as cutting gas so that the material burns and forms a pure stream of oxide that melts through the additional energy from burning. The cutting oxygen then forces the slag out of the cut piece part.

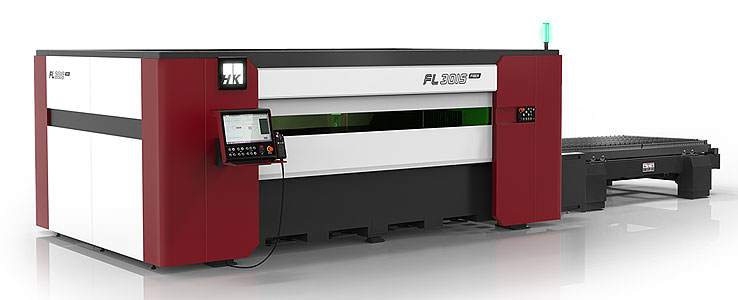

2022 top rated fiber laser cutting machine is designed for metal fabrication, including steel, titanium, aluminum, brass, copper, alloy, gold, silver, and iron with different laser powers (1000W, 1500W, 2000W). Now the affordable fiber laser cutter for sale at a low price, with the best fiber laser cutting system service and support.